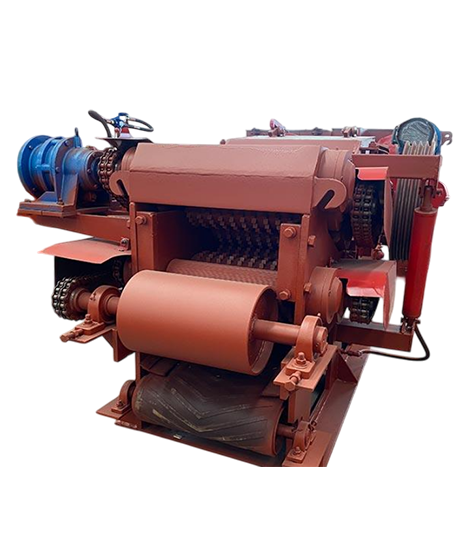

Veneer Wood Chipper Machine Manufacturer

The Wood Veneer Chipper by Techno Engineering Hub is specially designed to process veneer waste, plywood offcuts, and thin wood sheets into uniform chips. This machine is an essential solution in plywood, MDF, pulp & paper, and biomass industries for efficient recycling and resource recovery.

Key Features & Advantages

- Capacities ranging from 4 to 28 TPH depending on model

- Handles veneer waste with feed widths from 180 mm to 1050 mm

- Produces consistent chip sizes of 30–34 mm

- Heavy-duty steel construction with wear-resistant knives

- Stable feeding system with compression rolls to prevent jams

- Designed for continuous operation in industrial environments

- Applications: plywood, MDF, pulp mills, biomass energy, and recycling plants

Technical Specifications – Example Models

| Model | Feed Size (mm) | Rotor Dia. (mm) | Blades | Chip Size (mm) | Power (kW) | Capacity (TPH) |

|---|---|---|---|---|---|---|

| SWC-18/50 | 180×500 | 650 | 2 | 30 | 55 | 4–6 |

| SWC-22/68 | 220×680 | 800 | 2 | 30 | 110 | 6–10 |

| SWC-24/75 | 240×750 | 800 | 2–4 | 30 | 132 | 8–14 |

| SWC-33/105 | 330×1050 | 1000 | 2–4 | 34 | 200–250 | 12–20 |

| SWC-40/105 | 400×1050 | 1300 | 2–4 | 34 | 315 | 18–28 |

Working Principle

Veneer waste is fed into the machine using conveyors or feedworks equipped with compression rolls. The rotor drum, fitted with sharp knives, rotates at high speed and shears veneer sheets against a fixed anvil. This ensures efficient cutting into uniform chips. Chip size is controlled by adjusting the feed speed and knife projection

Applications

Wood veneer chippers are widely used in industries such as: - Plywood and MDF manufacturing - Pulp & Paper mills - Biomass and pellet production - Waste wood recycling for energy and feedstock