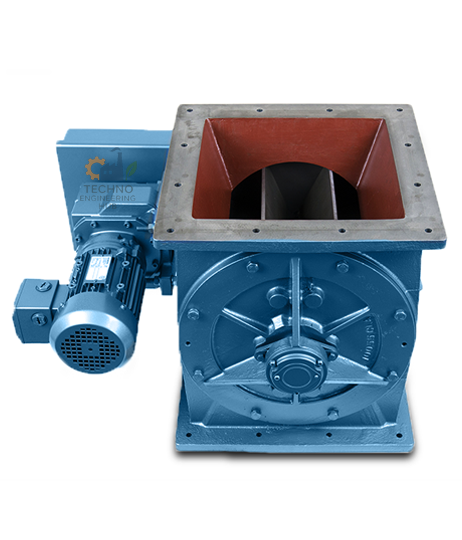

|Airlock Rotary Valves

High-Performance Airlock Rotary Valves for Material Handling

Airlock rotary valves are critical components used in bulk material handling systems for controlled feeding, metering, and airlock sealing. They are widely used in industries such as cement, food processing, power plants, chemical, and pharmaceuticals for dust collection systems, pneumatic conveying, and feeding applications

Applications:

- Dust collection systems (bag filter / cyclone discharge)

- Pneumatic conveying of powders & granules

- Feeding coal, cement, fly ash, grains, flour, sugar, plastics

- Controlled discharge from silos, hoppers, and bins

- Power plants, cement plants, food & pharma industries

| Parameter | Details |

|---|---|

| Body Material | Cast Iron / Mild Steel / Stainless Steel (SS304, SS316) |

| Rotor Type | Fixed blade / Adjustable blade / Open end / Closed end |

| Rotor Blades | 6 to 12 blades (depending on design) |

| Size Range | 150 mm to 600 mm (custom available) |

| Capacity | 0.5 m³/hr to 150 m³/hr |

| Operating Pressure | Up to 1.5 bar differential pressure |

| Operating Temperature | -20°C to 250°C (higher with special design) |

| Drive Type | Direct drive / Chain drive / Gear drive |

| Sealing Options | Gland packing / Lip seals / Mechanical seals |

| Surface Finish | Painted / Powder coated / Polished (for food & pharma) |

| Applications | Dust collection systems, pneumatic conveying, silo discharge |

Key Features & Benefits:

- Maintains airlock to prevent pressure loss

- Uniform material feeding and discharge

- Heavy-duty and durable construction

- Available in cast iron, MS, or stainless steel

- Various rotor designs for different materials

- Easy maintenance and cleaning options